NBV Quality

Pursuing the World’s Highest Standards for Technology. That is NBV Quality.

5/1000mm. 800ºC. 30 megapascals. This shows our basis for high quality.

These three keywords show the world renowned quality of NBV metal touch ball valves.

Balls are precision manufactured to a circularity of 5/1000mm. The sheet which accepts the ball and the valve itself are constructed with the same minute precision. NBV’s metal touch ball valve has exceptional power and durability. The metal touch ball valve demonstrates its sealability through the connection of precisely machined parts which lets it withstand and work in extreme high temperature environments up to 800ºC and high pressure regions up to 30 megapascals (approximately 300 kgf/cm2). Our ball valves really show off their unrivaled performance when dealing with hard to handle products such as powders, pellets and slurries which are difficult for other types of valves to handle.

Wide Scope of Applications from the Standard 200ºC Valve Up to High Temperatures of 800ºC.

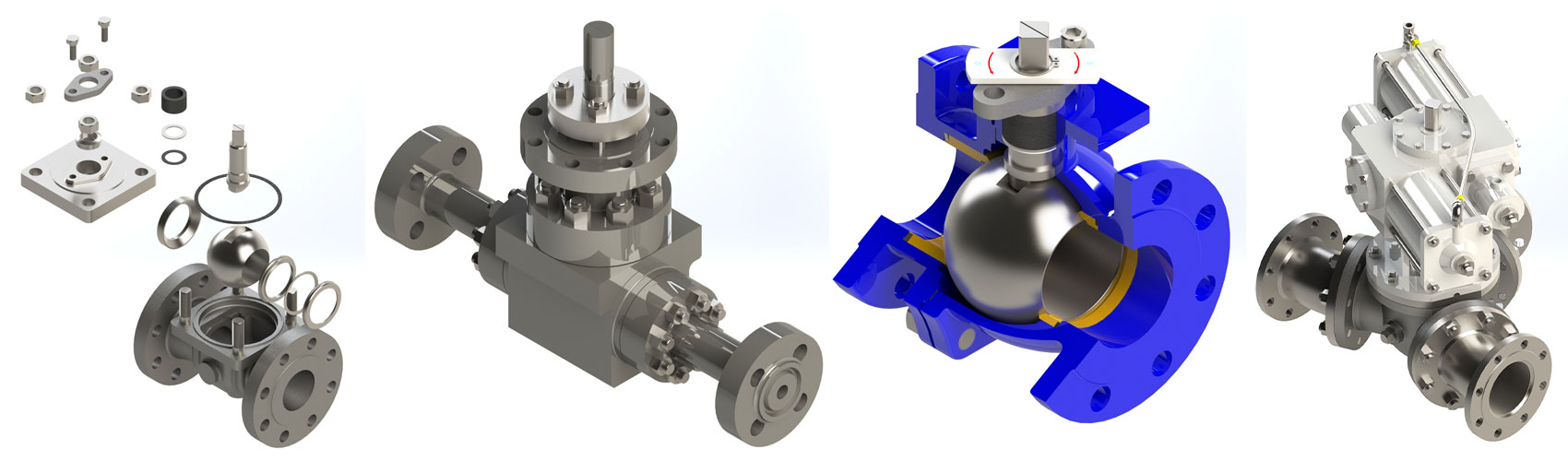

NBV’s metal touch ball valves are mainly separated into two different types: the standard type which can be used in temperatures up to 200ºC and the high temperature valve for temperatures up to 800ºC. Usage applications include oil, steel, power generation, cement, polycrystalline silicon manufacturing, synthetic resin and others in the chemical field and many other environmental applications. In addition, these products have been used in test equipment and new equipment first being operated in a variety of fields and has also experienced usage environments for the first time. We are proud to offer a diverse lineup to meet all needs of our customers such as the standard 2-way valve design, 3-way valve, 4-way valve, 5-way valve, 6-way valve, 8-way valve, Y branch valve and many other specialty valves, valves with jacket and extreme high temperature and high pressure application valves.

Raw performance of 5/1000mm circularity

Unlike general ball valves with a Teflon resin finish, in the case of two hard metal materials, there is no flexibility to preserve a seal. That is why the circularity of the ball and the combined machining precision of the sheet is extremely important. NBV has achieved circular processing that is extremely precise through the development of our exclusive polisher. We have succeeded in maintaining an extremely tight seal by combining two metal pieces with zero room for error.

Preventing the seizing of metal and corrosion

When two metal pieces such as a ball and sheet come into contact there is no way to avoid the seizing phenomenon called galling. NBV uses patented technology to create a difference in hardness between the two metal pieces which prevents this sort of problem in advance. We have experience providing products with reliable performance in the steel (great for transporting coke) and oil refinery (great for the foreign material in oil) business. We are also actively involved in improving the material of metal itself through the cooperation of a university laboratory to combat corrosion from acid, alkaline, saline and other chemical materials and friction.

Reduce running costs with our unique adjustable valve

One of the characteristics of NBV products is our adjustable valves. This feature lets you repair metal consumable parts to reuse the valve which allows you to extend any major repairs of the valve itself which may be needed. Since many valves end with a short lifespan because they cannot be repaired, NBV products help you significantly reduce running costs.

Full Order System

The only high performance valves in the world that meet a variety of needs.

Even if the valve is great for high temperature, high pressure and transport of specialty products, a high level of performance that is right for the materials and location is required that does not exceed the specifications suitable for the application or purpose. Unlike mass produced uniform designs, our products are special ordered from individual products. We ask what types of products you will be transporting and their characteristics, the temperature and design pressure among other necessary specifications and any other requests you may have to proficiently hand manufacture a product that is just right for your individual application and operational environment. We make sure there are zero internal leaks at the time of shipment through our thorough pre-shipping inspection.

1995 – Obtained ISO9001 Certification

2005 – Obtained ISO14001 Certification

Process Flow